One-Way Slab vs. Two-Way Slab – One and two-way slabs are widely used in construction. This guide will clarify their definitions, distinctions, design factors, and uses in straightforward terms.

Introduction

Slabs are vital components of any structure, serving as flat surfaces for floors and ceilings. They help support the building’s weight and maintain stability. In civil engineering, slabs are categorized into two types: one-way slabs and two-way slabs. The classification hinges on how the load is transferred and the method of support.

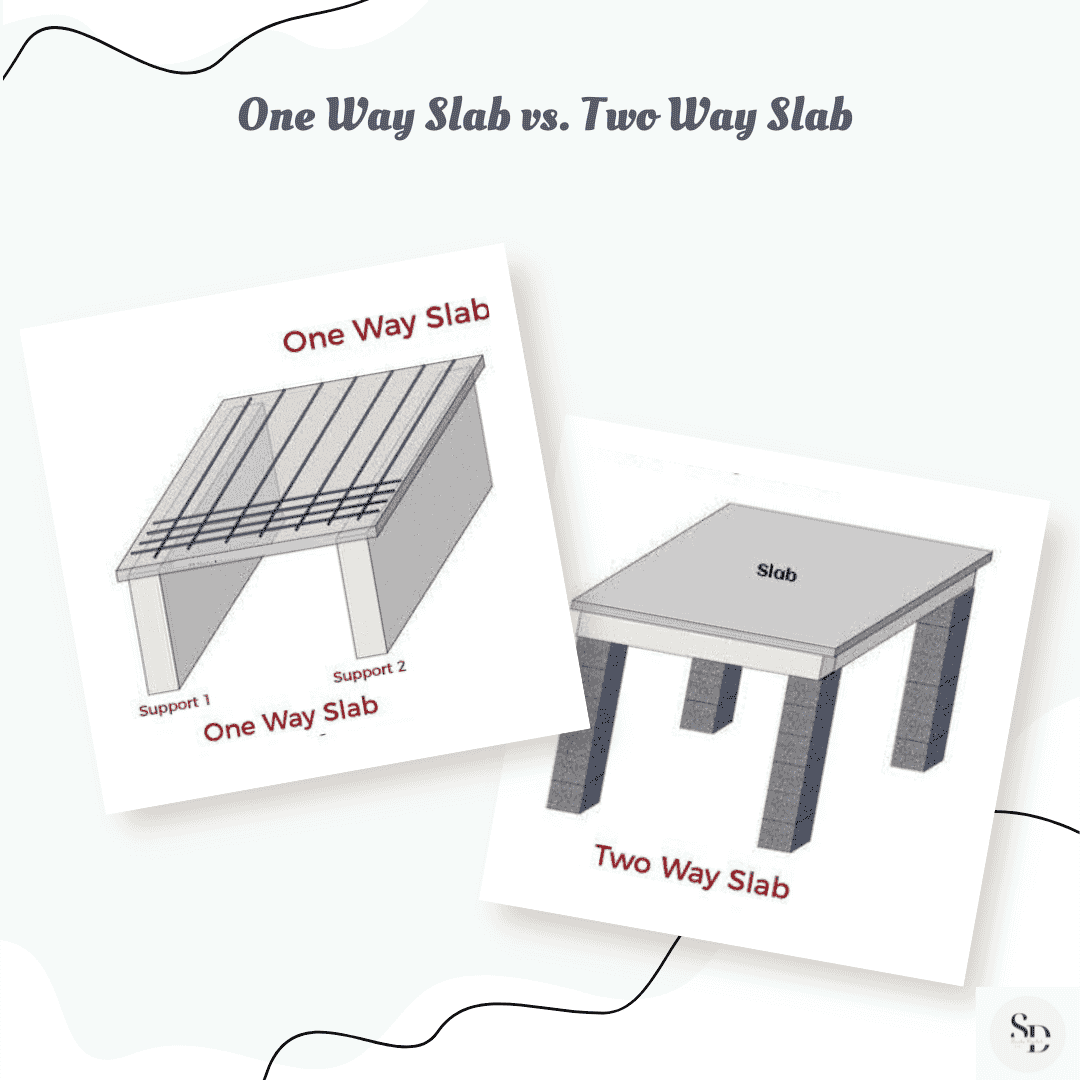

A one-way slab directs the load in a single direction, supported on two opposite sides. If the longer span (L) to the shorter span (B) ratio is greater than or equal to 2 (L/B ≥ 2), it qualifies as a one-way slab. The primary reinforcement in this type is aligned along the shorter span, as it bears most of the load. These slabs are typically found in verandahs, balconies, and cantilever structures.

Conversely, a two-way slab is supported on all four edges, allowing the load to be shared in both directions. This applies when the longer span (L) to shorter span (B) ratio is less than 2 (L/B < 2). In this instance, reinforcement is implemented in both directions to efficiently manage the load. Two-way slabs are commonly used in floors of multi-storey buildings and large halls that require uniform load distribution.

Recognizing the differences between one-way and two-way slabs is critical for selecting the appropriate type for a given structure. Proper selection guarantees structural integrity, cost efficiency, and safety in construction. This article delves into their primary differences, uses, and design factors comprehensively.

One-Way Slab vs. Two-Way Slab: A Detailed Comparison Based on 15 Factors

Choosing the right slab is crucial in construction, impacting structural strength, cost, and efficiency. The distinctions between one-way slabs and two-way slabs include load distribution, reinforcement placement, and application. Below is an in-depth comparison grounded in 15 significant factors.

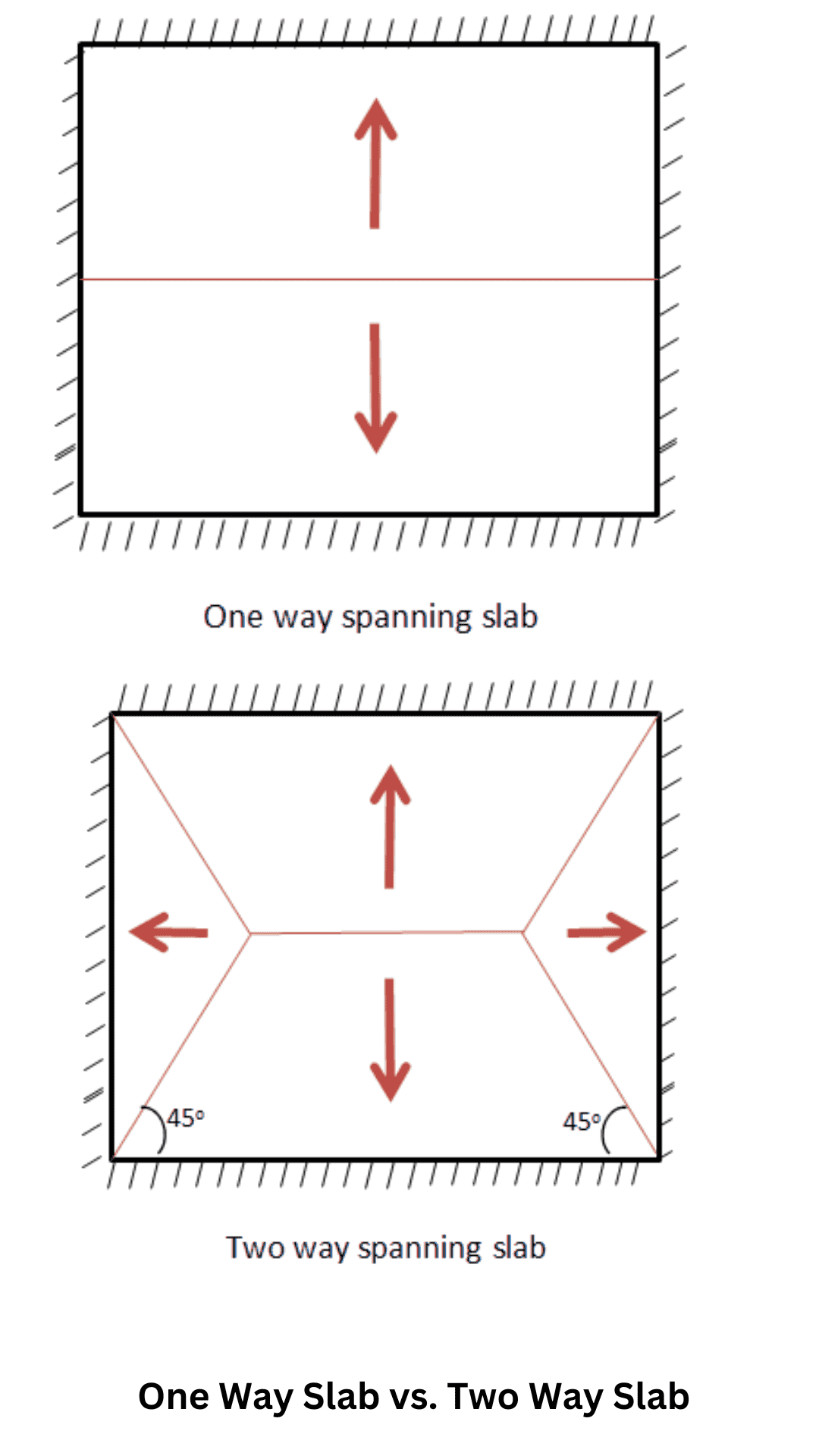

- Load Transfer Direction

- One-Way Slab: Distributes load solely in one direction (along the shorter span).

- Two-Way Slab: Distributes load across both directions (along both spans).

- Support Conditions

- One-Way Slab: Supported on two opposite edges.

- Two-Way Slab: Supported on all four edges.

- Aspect Ratio (L/B Ratio)

- One-Way Slab: Considered one-way if L/B ≥ 2.

- Two-Way Slab: Considered two-way if L/B < 2.

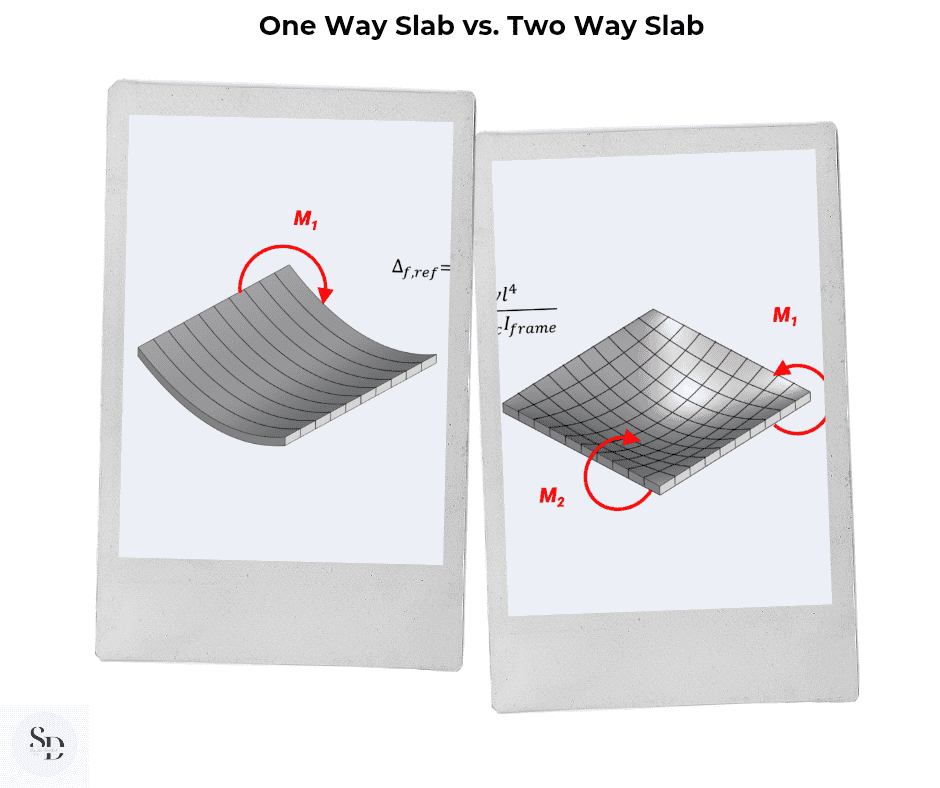

- Reinforcement Placement

- One-Way Slab: Main reinforcement is laid out in one direction (along the shorter span).

- Two-Way Slab: Main reinforcement is arranged in both directions.

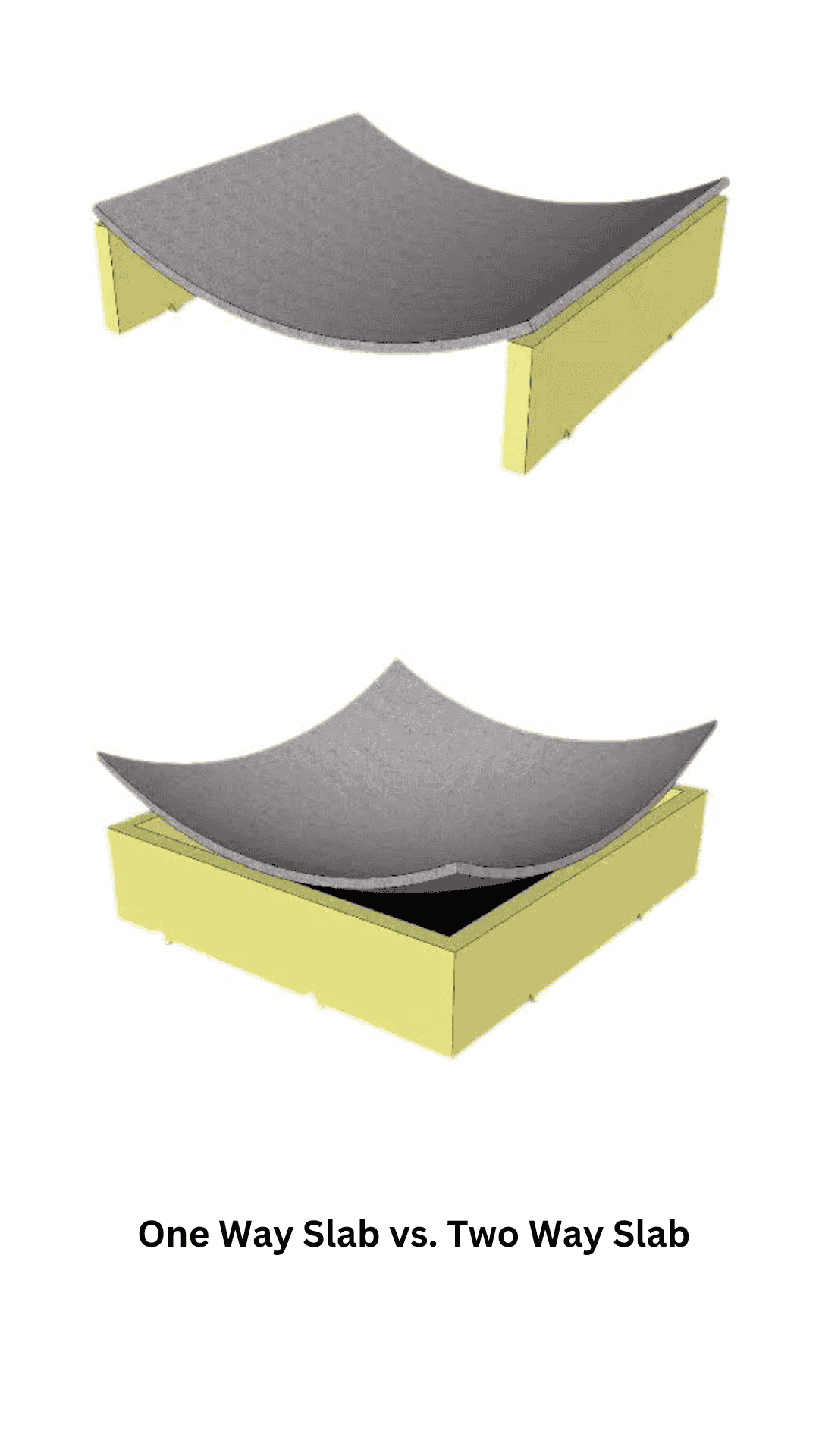

- Deflection Pattern

- One-Way Slab: Deflects in a cylindrical manner along one axis.

- Two-Way Slab: Deflects in a dish-like shape in both directions.

- Structural Behavior

- One-Way Slab: Functions like a beam supported on two sides.

- Two-Way Slab: Operates as a grid, evenly spreading load in both directions.

- Design Complexity

- One-Way Slab: Simpler to design due to single-direction load transfer.

- Two-Way Slab: More intricate to design because of dual load distribution.

- Construction Cost

- One-Way Slab: More economical due to reduced reinforcement and simpler formwork.

- Two-Way Slab: Costlier due to increased reinforcement needs.

- Formwork Requirement

- One-Way Slab: Requires uncomplicated formwork since it is supported on two edges.

- Two-Way Slab: Demands more elaborate formwork to accommodate all supports.

- Load-Carrying Capacity

- One-Way Slab: Suitable for lighter loads.

- Two-Way Slab: Capable of handling heavier loads due to even load sharing.

- Thickness of Slab

- One-Way Slab: Typically thicker than two-way slabs for the same span.

- Two-Way Slab: Generally thinner, as it distributes load more efficiently.

- Span Length

- One-Way Slab: Best for longer spans (but requires depth).

- Two-Way Slab: Effective for shorter spans (up to 6m x 6m).

- Crack Resistance

- One-Way Slab: More likely to crack along the longer span.

- Two-Way Slab: Less prone to cracking due to uniform load distribution.

- Common Applications

- One-Way Slab: Used in verandahs, balconies, pathways, and cantilevers.

- Two-Way Slab: Employed in multi-storey structures, halls, and commercial buildings.

- Indian Standard Code (IS Code)

- One-Way Slab: Designed according to IS 456:2000, focusing on unidirectional load.

- Two-Way Slab: Designed under IS 456:2000, considering multidirectional load.

One-Way Slab vs. Two-Way Slab (One-Liner Differences)

- Load Distribution: One-way slabs load in one direction; two-way slabs distribute it in two.

- L/B Ratio: One-way slabs have L/B ≥ 2, while two-way slabs have L/B < 2.

- Reinforcement: One-way slabs have reinforcement in one direction; two-way slabs have it in both.

- Support Condition: One-way slabs are supported on two edges; two-way slabs on all four edges.

- Deflection Pattern: One-way slabs bend in one direction; two-way slabs bend in a dish-like shape.

- Steel Requirement: Two-way slabs need more steel than one-way slabs.

- Bending Moment Calculation: One-way slabs follow simple beam formulas, while two-way slabs use IS 456 moment coefficients.

- Common Applications: One-way slabs are prevalent in corridors, balconies, and small rooms; two-way slabs are typical in larger areas and heavy-load floors.

- Economic Factor: One-way slabs are more affordable for small spans; two-way slabs are cost-effective for large spans.

- Thickness Requirement: Two-way slabs often require extra thickness due to multidirectional load transfer.

- Structural Efficiency: Two-way slabs distribute loads better, minimizing failure risks.

- Construction Time: One-way slabs are generally faster to build than two-way slabs.

- Shuttering Requirement: Two-way slabs need more intricate shuttering than one-way slabs.

- Example Structures: One-way slabs are standard in homes, while two-way slabs are used in commercial buildings.

- Moment Resistance: Two-way slabs resist moments in both directions; one-way slabs do so in one.

What is a Slab?

A slab is a horizontal structural element that supports loads in buildings. It evenly distributes weight to the beams, columns, or walls below and serves as floors, roofs, or ceilings.

Types of Slabs According to Indian Standards

According to IS 456:2000, slabs come in various types:

- One-Way Slab (Load transmitted in one direction)

- Two-Way Slab (Load transmitted in both directions)

- Flat Slab (No beams; directly supported by columns)

- Ribbed or Waffle Slab (Grid pattern reduces weight)

- Hollow-Core Slab (Lightweight with hollow sections)

- Precast Slab (Factory-made, moved to site)

- Post-Tensioned Slab (Uses high-strength steel cables for reinforcement)

- Continuous Slab (Extends over multiple supports without joints)

- Cantilever Slab (Projects beyond support without extra columns)

Indian Standard Code (IS Code) for Slab Design

Slabs designed in reinforced concrete adhere to IS 456:2000, which outlines:

- Load calculations

- Reinforcement detailing

- Slab thickness specifications

- Deflection management

- Durability factors

Factors to Consider for Slab Design

When designing a slab, the following considerations are key:

- Load Type and Intensity (Dead load, live load, wind load, seismic load)

- Span Length (Shorter spans require less reinforcement; longer spans need deeper sections)

- Slab Thickness (Determined by deflection management and load capacity)

- Reinforcement Detailing (Placement of steel bars for strength and crack prevention)

- Material Properties (Concrete and steel quality)

- Support Conditions (Simply supported, fixed, continuous, or cantilevered)

- Deflection and Crack Control (Ensuring durability and serviceability)

- Construction Method (Precast or cast-in-situ slabs)

- Environmental Factors (Exposure to moisture, temperature changes, and chemical effects)

Advantages and Disadvantages of One-Way Slab and Two-Way Slab

Advantages of One-Way Slab

- Simple Design: Easy analysis and construction due to single-direction load transfer.

- Cost-Effective: Requires less reinforcement and formwork, lowering material and labor expenses.

- Suitable for Longer Spans: Efficiently covers long, narrow areas.

- Less Complicated Formwork: Simpler formwork contributes to quicker construction.

- Ideal for Residential Use: Commonly employed in verandahs, balconies, and small residential buildings.

Disadvantages of One-Way Slab

- Higher Thickness Requirement: Thicker sections may be needed for longer spans to manage deflection.

- Less Efficient Load Distribution: Transfers load in one direction, leading to uneven stress distribution.

- More Prone to Cracks: Unidirectional bending may lead to cracking along the length.

- Not Suitable for Heavy Loads: Less effective for large structures needing uniform load distribution.

Advantages of Two-Way Slab

- Even Load Distribution: Load is shared in both directions, lowering stress on individual supports.

- Thinner Slab Design: Requires less thickness compared to one-way slabs.

- Better Crack Resistance: Less likely to crack due to uniform load distribution.

- Efficient for Large Areas: Ideal for multi-storey buildings, commercial spaces, and halls.

- Greater Load-Carrying Capacity: Supports heavier loads due to dual-direction reinforcement.

Disadvantages of Two-Way Slab

Higher Formwork Requirements: More extensive formwork support is necessary due to bidirectional load transfer.

More Expensive: Increased steel reinforcement and complex formwork lead to higher costs.

Difficult to Construct: Complex reinforcements and support systems need skilled labor.

Not Ideal for Long, Narrow Spans: Better suited for square or nearly square shapes.

Conclusion

Slabs play a crucial role in building construction, providing the necessary strength and stability. Choosing between a one-way slab and a two-way slab depends on multiple factors like span length, load type, cost, and construction feasibility.

If the span is long and narrow, a one-way slab is preferable due to its simple design and cost-effectiveness. However, if equal load distribution and structural strength are priorities, a two-way slab is the better choice, especially for multi-storey buildings and commercial spaces.

Understanding these differences allows civil engineers, architects, and builders to optimize material use, reduce costs, and enhance structural safety. Proper slab selection ensures that buildings are durable, efficient, and built to last.

Thank You Note

Thank you for taking the time to read this comprehensive comparison of one-way slabs and two-way slabs. We hope this blog has helped clarify the key differences, advantages, and applications of both types of slabs. Whether you’re a civil engineering student, a professional engineer, or someone interested in construction, We appreciate your interest in learning more about structural design.

If you found this information useful, feel free to share it with others in the construction industry. Stay curious and keep building strong structures!

For more comparisons and insights, visit our blog regularly. If you have any questions or suggestions, feel free to leave a comment or contact us directly. Happy building!

Frequently Asked Questions (FAQs)

Can we use both one-way and two-way slabs in the same building?

Which type of slab is stronger?

Where are two-way slabs commonly used?

Where are one-way slabs commonly used?

Which type of slab is cheaper to construct?

How do we determine if a slab is one-way or two-way?

If L/B ≥ 2, it is a one-way slab.

If L/B < 2, it is a two-way slab.

What is the main difference between a one-way slab and a two-way slab?

Note for Readers

If you’d like to read this blog in your regional language or any other international language, simply click on the Google Translator option located in the bar at the top of the page. This feature allows you to select your preferred language and enjoy the content in a way that’s comfortable for you. We hope this makes your reading experience more enjoyable and accessible!

Disclaimer

This blog is intended for educational and informational purposes only. The information provided here is based on general construction practices and Indian Standard Code IS 456:2000. However, actual design and implementation should always be carried out by a licensed civil engineer or structural expert to ensure compliance with safety and building regulations. The author is not responsible for any decisions made based on this information.

For more exciting topics, explore our other articles here

Brick Masonry vs Stone Masonry

Difference Between OPC and PPC Cement

ChatGPT vs DeepSeek: Which AI Chatbot Reigns Supreme in 2025?

5 Comments