Soil Test: Field vs Lab – Discover the key differences between soil testing in the field and in the laboratory. This in-depth blog on Soil Test: Field vs Lab explores types of tests, importance in construction, IS codes, and soil properties as per Indian standards.

Table of Contents

Introduction

Soil – it’s the very ground beneath our feet, yet most of us overlook its importance until we start building on it. For engineers and builders, soil isn’t just dirt; it’s a foundation that decides the strength, stability, and life of any structure. From towering skyscrapers to humble homes, the success of every construction project begins with understanding the soil.

In India, where soil types vary drastically from region to region – from sandy deserts of Rajasthan to clayey coastal plains – getting the soil right is crucial. That’s why soil testing is not just a formality, it’s a necessity. But here comes the big question: should we rely on tests done at the construction site or those performed in well-equipped laboratories?

This blog breaks it all down for you. We’ll explore what exactly soil testing is, the difference between field and lab tests, how they’re conducted, their significance, and which IS codes govern them. Whether you’re a civil engineering student, a practicing site engineer, or just curious about how buildings stand strong for decades – you’re in the right place.

Let’s get our hands dirty and dive deep into the world of Soil Test: Field vs Lab.

Properties of Soil

Understanding soil properties is essential before starting any construction project. These properties influence how soil behaves under different environmental and loading conditions.

1. Physical Properties

- Grain Size Distribution (IS 2720 Part 4): Determines the percentage of sand, silt, and clay.

- Moisture Content (IS 2720 Part 2): The amount of water present in the soil.

- Specific Gravity (IS 2720 Part 3): The ratio of the density of soil solids to the density of water. Typical values range from 2.60 to 2.85 for inorganic soils.

- Bulk Density: Mass of soil per unit volume (including voids).

- Dry Density: Mass of soil solids per unit volume of soil.

2. Consistency Properties

- Atterberg Limits (IS 2720 Part 5):

- Liquid Limit (LL): Water content at which soil changes from plastic to liquid state.

- Plastic Limit (PL): Water content where soil just begins to crumble when rolled.

- Plasticity Index (PI) = LL – PL; indicates the plasticity range.

3. Engineering Properties

- Shear Strength (IS 2720 Part 13): Resistance against sliding failure. Measured via triaxial or direct shear tests.

- Compaction (IS 2720 Part 7 & 8): Determines Optimum Moisture Content (OMC) and Maximum Dry Density (MDD).

- Permeability (IS 2720 Part 17): Ability of soil to allow water flow through it.

- Consolidation (IS 2720 Part 15): Time-dependent settlement under load.

Types of Soil

Based on origin, composition, and behavior, soils can be classified into several types:

- Clayey Soil: Fine particles, high plasticity, low permeability.

- Silty Soil: Smooth texture, poor drainage, moderate strength.

- Sandy Soil: Coarse particles, good drainage, less cohesive.

- Gravelly Soil: Very coarse particles, excellent drainage.

- Loamy Soil: Mix of sand, silt, and clay – considered ideal for agriculture.

- Peaty Soil: Rich in organic matter, compressible and weak.

- Black Cotton Soil: Highly expansive clay, swells in water, dangerous for foundations.

- Laterite Soil: Rich in iron, found in high rainfall areas, hardens on exposure.

Symbols and Groups

- GW: Well-graded gravel

- GP: Poorly graded gravel

- SW: Well-graded sand

- SP: Poorly graded sand

- CL: Clay with low plasticity

- CH: Clay with high plasticity

- ML: Silt with low plasticity

- MH: Silt with high plasticity

- OL/OH: Organic soils

- PT: Peat

Key Technical Terms

1. Specific Gravity (G)

- Indicates the heaviness of soil solids.

- Normal range: 2.60 – 2.75 for inorganic soils.

- Test Code: IS 2720 Part 3

2. Density

- Bulk Density (ρ) = Weight of soil / Total volume

- Dry Density = Weight of solids / Total volume

- Affects compaction and strength behavior.

3. Void Ratio (e) and Porosity (n)

- Void Ratio: Ratio of void volume to solid volume.

- Porosity: Percentage of void space.

4. Degree of Saturation (S)

- Percentage of voids filled with water.

5. Water Content (w)

- Crucial for assessing compaction and plasticity.

IS Codes Related to Soil

- IS 1498:1970 – Classification and identification of soils for general engineering purposes.

- IS 2720 (Part 1 to Part 40) – Series covering all methods of tests for soils like moisture content, specific gravity, shear strength, permeability, consolidation, compaction, etc.

- IS 1892:1979 – Guidelines for subsurface investigations for foundations.

- IS 10379:1982 – Code of practice for field testing of soils.

- IS 8009 (Part 1 and 2) – Load bearing capacity testing of soil using plate load test and penetration tests.

- IS 1200 (Various Parts) – Methods of measurement for earthwork, excavation, and backfilling.

- IS 1904:1986 – Design and construction of foundations in soils – general requirements.

- IS 2131:1981 – Standard penetration test (SPT) procedure.

- IS 6403:1981 – Determination of bearing capacity using standard penetration test data.

Classification of Soil Strata

This classification is usually based on consistency, strength, and penetration resistance (especially using the Standard Penetration Test – SPT as per IS 2131):

1. Soft Soil

- Very low shear strength

- Easily deformable

- SPT N-value: 0–4 blows

- Common Types: Clayey soils, silty soils, peaty soils, organic soils

- Found in: Riverbeds, marshy lands, coastal regions (e.g., West Bengal, Kerala, Sundarbans, parts of Assam)

2. Medium Soil

- Moderately compressible

- Moderate load-bearing capacity

- SPT N-value: 5–15 blows

- Common Types: Well-compacted sandy soil, loam, mixed deposits of clay and sand

- Found in: Urban outskirts, alluvial plains (e.g., Delhi NCR, parts of UP, Bihar plains)

3. Hard/Dense Soil or Hard Strata

- High shear strength

- Difficult to excavate without mechanical tools

- SPT N-value: >15–50+ blows

- Common Types: Gravelly soils, dense sands, murrum, laterite, weathered rock

- Found in: Plateaus, rocky terrains (e.g., Deccan Plateau, parts of Rajasthan, Karnataka, Maharashtra)

Uses of Soil in Infrastructure and Industry

Soil is not just the ground we walk on—it plays a critical role in almost every infrastructure project and industrial application. From construction to landscaping, from road building to earth embankments, soil is a natural building material that’s versatile, abundant, and essential.

1. Foundation Material in Construction

- Primary Use: Every structure—whether it’s a home, dam, or skyscraper—rests on soil. The strength and type of soil determine the design of foundations.

- Good Soil for Foundation: Hard, dense, and well-drained soils like gravelly or sandy soil.

- Poor Soil: Soft clay, peat, or expansive black cotton soil unless treated.

2. Soil for Earthworks and Embankments

- Highway Construction: Soil is used for building embankments for roads, railways, and airstrips. Suitable soils are selected and compacted layer by layer.

- Embankments/Dykes: Used in flood control, irrigation canals, and reservoir linings.

3. Soil Backfilling

- After laying foundations, pipes, or retaining walls, backfilling is done using selected soil to ensure stability and support.

- Backfilling Soil Must Be:

- Well-graded

- Free from organic matter

- Properly compactable

- With low swelling/shrinkage

- Common Types Used: Red earth, murum, laterite, well-graded sand or sandy clay.

4. Soil in Bag Filling / Sandbags

Used for:

- Flood protection (temporary levees)

- Temporary retaining walls

- Military defense and bunkers

- Emergency roadblocks

- Materials: Well-graded sand or coarse silt with minimal clay content to ensure easy filling and good weight.

5. Landscaping and Gardening

- Soil is essential for growing plants and trees in residential and commercial landscaping.

- Loamy soil, rich in nutrients and organic matter, is ideal for horticulture.

6. Soil as a Raw Material

- Brick Industry: Clayey soil is used to make bricks, tiles, and earthen pots.

- Pottery: Fine, plastic clays are shaped and fired.

- Cement Industry: Soil (rich in lime and clay) is part of raw mix for cement.

Environmentally Friendly Uses of Soil

As sustainable development gains importance, soil-friendly and eco-sensitive practices are becoming more widespread:

1. Green Backfilling

- Using recyclable soil (from site excavation) instead of importing new material.

- Mixing natural binders like lime or fly ash to improve soft soils instead of chemicals.

2. Soil Bio-Engineering

- Combining vegetation and soil for slope protection, preventing erosion without concrete or steel.

- Popular for riverbank stabilization, hilly road construction, and eco-parks.

3. Rain Gardens and Recharge Pits

- Specially designed soil beds with layers of sand and gravel help recharge groundwater and manage stormwater runoff.

4. Use of Soil in Green Roofs

- Lightweight soil mixes are used on rooftops to support plant life and reduce urban heat.

5. Natural Wastewater Filtration

- Soil-based wetlands are designed to treat sewage using natural soil microbes and plant roots.

Best Practices to Use Soil Responsibly

- Avoid using topsoil from fertile agricultural land.

- Reuse excavated soil wherever feasible.

- Avoid contamination of soil with cement, oil, or construction waste.

- Conduct proper geotechnical investigation before selecting soil for any application.

Tests for Soil

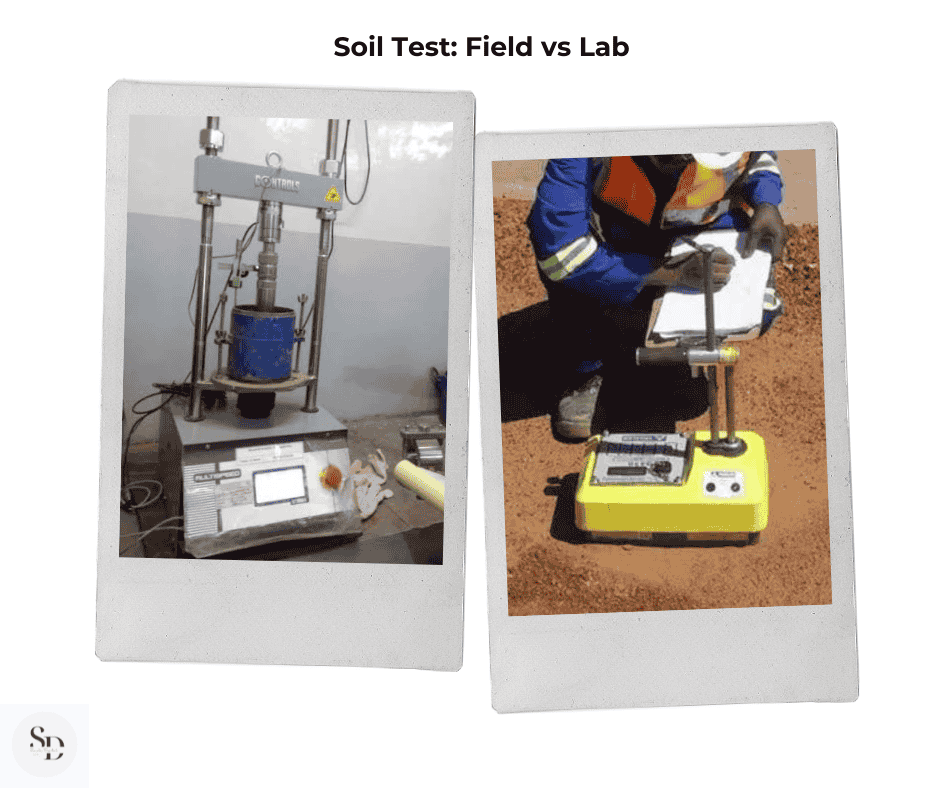

Field Tests for Soil (as per IS standards)

- Visual Inspection Test

- Dry Strength Test

- Toughness Test

- Dilatancy Test

- Organic Content Test (by smell and color)

- Moisture Content (approximate by feel)

- Standard Penetration Test (SPT) – IS 2131

- Dynamic Cone Penetration Test (DCPT) – IS 4968 Part 1 to 3

- Plate Load Test – IS 1888

- Field Density Test (Core Cutter Method) – IS 2720 Part 29

- Field Density Test (Sand Replacement Method) – IS 2720 Part 28

- Vane Shear Test – IS 4434

- Percolation Test – IS 11233

- California Bearing Ratio (CBR) – Field Test – IS 2720 Part 31

Laboratory Tests for Soil (as per IS standards)

- Grain Size Analysis – IS 2720 Part 4

- Atterberg Limits (Liquid, Plastic, Shrinkage) – IS 2720 Part 5

- Specific Gravity Test – IS 2720 Part 3

- Moisture Content Test – IS 2720 Part 2

- Compaction Test (Proctor Test) – IS 2720 Part 7 and 8

- Unconfined Compression Test – IS 2720 Part 10

- Direct Shear Test – IS 2720 Part 13

- Triaxial Shear Test – IS 2720 Part 11

- Consolidation Test – IS 2720 Part 15

- Permeability Test – IS 2720 Part 17

- Swelling Pressure Test – IS 2720 Part 41

- Free Swell Index – IS 2720 Part 40

- Chemical Analysis of Soil (pH, Sulphates, Chlorides, etc.) – IS 2720 Part 26

- California Bearing Ratio (CBR) – Lab Test – IS 2720 Part 16

Field Tests for Soil

1. Visual Inspection Test

Purpose: To make a quick judgment about the type and quality of soil based on its appearance.

Procedure:

- Look at the soil color, texture, structure, and moisture.

- Feel it by hand – is it gritty (sand), sticky (clay), or smooth (silt)?

- Observe its behavior when dry and wet.

- Note any visible organic matter, roots, or stones.

Use: Useful for initial site assessments before formal testing. Helps identify the soil strata changes.

2. Dry Strength Test

Purpose: To check the cohesive strength of fine-grained soil (mainly clay) when dry.

Procedure:

- Take a moist soil sample and make a pat (coin size).

- Let it dry completely in the sun or shade.

- Try to break it with your fingers or thumb.

Observation:

- If it breaks with difficulty → High dry strength → Likely clayey soil.

- If it breaks easily → Low dry strength → Possibly silty soil.

Use: Used to differentiate between clay and silt in the field.

3. Toughness Test

Purpose: To assess the plasticity and resistance of soil to deformation when moist.

Procedure:

- Make a plastic thread from moist soil.

- Roll it until it starts crumbling at about 3 mm diameter.

- Try to fold it and knead it.

Observation:

- Very stiff and resists folding → High toughness → Plastic clay.

- Crumbles easily → Low toughness → Silt or non-plastic clay.

Use: Helps to identify clayey soils and check plasticity index visually.

4. Dilatancy Test

Purpose: To identify silt content in the soil and determine its behavior under sudden loading.

Procedure:

- Take moist soil and place it in your palm.

- Shake the hand horizontally for a few seconds.

- Observe water appearing on the surface.

Observation:

- Water appears quickly and disappears when squeezing → Silty soil.

- No water appears → Likely clayey soil.

Use: Used in the field to differentiate silt from clay.

5. Organic Content Test (By Smell & Color)

Purpose: To detect organic matter (like roots, leaves, or decomposed material) in the soil.

Procedure:

- Smell the soil – strong earthy or foul smell may indicate organic content.

- Observe dark black or brown coloration.

- Burn a small piece to see if it emits smoke or smell.

Observation:

- Strong smell or dark color → High organic matter → Peaty or organic soil.

- Dull or neutral smell → Inorganic soil.

Use: Important for sites near rivers, swamps, or reclaimed land.

6. Moisture Content Test (Approximate by Feel)

Purpose: To get a quick idea of soil moisture on-site before excavation or compaction.

Procedure:

- Take a small soil sample in your hand.

- Squeeze it tightly and open the hand.

Observation:

- Stays in shape but crumbles with touch → Optimum moisture.

- Stays sticky and wet → High moisture.

- Falls apart easily → Dry soil.

Use: Important for knowing if the soil is ready for compaction or needs drying/wetting.

7. Standard Penetration Test (SPT) – IS 2131

Purpose: To determine the relative density and strength of cohesionless soils like sand and gravel.

Procedure:

- A split spoon sampler is driven into the soil at the bottom of a borehole.

- A 63.5 kg hammer is dropped from a height of 750 mm.

- The number of blows required to drive the sampler 30 cm (in three 10 cm intervals) is recorded.

Result:

- The number of blows for the last 20 cm is called the SPT N-value.

- Higher N-values → Dense soil; lower N-values → Loose soil.

Use: Common in foundation design and geotechnical analysis.

8. Dynamic Cone Penetration Test (DCPT) – IS 4968 Part 1 to 3

Purpose: To assess the strength and compactness of soil strata, especially in granular soils.

Procedure:

- A cone is driven into the soil using a hammer.

- The number of blows for a specific penetration depth is recorded.

Result:

- More blows → Denser soil.

- Less blows → Loose or soft soil.

Use: Useful for rapid assessment of soil bearing capacity at multiple locations.

9. Plate Load Test – IS 1888

Purpose: To determine the bearing capacity and settlement of soil under actual loading.

Procedure:

- A rigid steel plate (usually 300 mm to 750 mm dia.) is placed at foundation level.

- Load is applied in increments, and settlement is observed.

Result: Load vs. settlement graph helps to calculate safe bearing capacity and modulus of subgrade reaction.

Use: Used in designing foundations for buildings, pavements, and industrial floors.

10. Field Density Test (Core Cutter Method) – IS 2720 Part 29

Purpose:

To determine the in-situ density of cohesive soils (clay, silt).

Procedure:

A cylindrical core cutter is driven into the soil.

Soil inside the cutter is weighed and its volume measured.

Result:

Field Density = Weight of soil / Volume of core.

Compare with lab Proctor test to check compaction quality.

Use: Ideal for compacted earthwork quality checks in cohesive soils.

11. Field Density Test (Sand Replacement Method) – IS 2720 Part 28

Purpose: To determine the in-situ density of granular and non-cohesive soils.

Procedure:

- A hole is dug at the test site.

- The soil removed is weighed.

- The hole is filled with calibrated sand, and the amount of sand used is measured.

Result: Density = Mass of excavated soil / Volume of hole (from sand volume).

Use: Preferred method in granular soils where core cutter can’t be used.

12. Vane Shear Test – IS 4434

Purpose: To measure the shear strength of soft to very soft clays in-situ.

How it’s done:

- A four-bladed vane is inserted into undisturbed soft clay.

- It is rotated using torque, and the resistance is recorded.

Result: Direct reading of undrained shear strength in kN/m².

Use: Highly useful in marine clay or very soft soil where other tests fail.

13. Percolation Test – IS 11233

Purpose: To determine how fast water moves through the soil – i.e., the permeability.

Procedure:

- A test pit is dug and filled with water.

- Time taken for the water to seep into the soil is recorded.

Result:

- Faster percolation → High permeability (gravel, sand).

- Slow percolation → Low permeability (clay).

Use: Important in septic tank design, rainwater harvesting, and drainage planning.

14. California Bearing Ratio (CBR) – Field Test – IS 2720 Part 31

Purpose: To evaluate the load-bearing capacity of subgrade soil for roads and pavements.

Procedure:

- A plunger is pressed into the soil at a constant rate.

- Resistance of soil to penetration is measured.

Result:

- CBR value = (Test load / Standard load) × 100

- Higher CBR → Stronger soil suitable for road base/subgrade.

Use: Essential for highway and pavement design.

Laboratory Tests for Soil

1. Moisture Content Test (IS 2720 Part 2)

Purpose: To determine the natural water content (also known as moisture content) of soil, which is essential for understanding compaction, strength, and consistency.

Apparatus Used:

- Weighing balance (accuracy 0.01g)

- Moisture cans

- Oven (105°C to 110°C)

- Desiccator

Procedure:

1. Weigh an empty moisture can (W1).

2. Fill it with moist soil and weigh (W2).

3. Place in an oven at 105–110°C for 24 hours.

4. Remove, cool in a desiccator, and weigh again (W3).

Formula: Moisture content (w) = [(W2 – W3) / (W3 – W1)] × 100

Result: Expressed as a percentage of the dry weight of the soil.

2. Specific Gravity Test (IS 2720 Part 3)

Purpose: To find the specific gravity of soil solids, which is crucial in many calculations such as void ratio and degree of saturation.

Apparatus Used:

- Pycnometer or density bottle

- Weighing balance

- Oven

- Distilled water

- Desiccator

Procedure (Pycnometer Method):

1. Weigh empty pycnometer (W1).

2. Add dry soil (about 200g) and weigh (W2).

3. Add distilled water and remove air bubbles, then weigh (W3).

4. Empty and refill pycnometer with water only, weigh (W4).

Formula: G = [(W2 – W1) / (W2 – W3) – (W4 – W1)]

Result: G is typically between 2.6–2.75 for mineral soils.

3. Grain Size Analysis (Sieve Analysis) – IS 2720 Part 4

Purpose: To determine the particle size distribution of coarse-grained soil (sand and gravel).

Apparatus Used:

- Standard IS Sieves

- Sieve shaker

- Weighing balance

- Brush and trays

Procedure:

1. Dry soil sample (500 g to 1 kg) is placed in the top sieve of a stack.

2. Shake for 10–15 minutes using a mechanical shaker.

3. Weigh the retained soil on each sieve.

Result:

- Data used to plot a gradation curve, and determine percentage passing or retained on each sieve.

- Used to classify soil (well-graded, poorly graded, etc.).

4. Hydrometer Analysis – IS 2720 Part 4

Purpose: To analyze the grain size distribution of fine-grained soils (silt and clay) not measurable by sieves.

Apparatus Used:

- Hydrometer

- Sedimentation cylinder

- Dispersing agent (sodium hexametaphosphate)

- Stopwatch

- Thermometer

- Mechanical stirrer

Procedure:

1. Prepare soil suspension with dispersing agent.

2. Fill the graduated cylinder and mix well.

3. Place the hydrometer in the suspension and record readings at regular intervals.

4. Note temperature and apply corrections.

Result: A graph of % finer vs particle size is plotted. Helps in identifying clay, silt fractions in the soil.

5. Atterberg Limits Test (IS 2720 Part 5)

Purpose: To determine Liquid Limit (LL), Plastic Limit (PL), and Shrinkage Limit (SL) of fine-grained soil which helps in soil classification and plasticity analysis.

Apparatus Used:

- Casagrande Liquid Limit device

- Grooving tool

- Glass plate

- Oven

- Moisture cans

- Shrinkage dish (for SL)

Procedure:

For Liquid Limit (LL):

1. Soil paste is placed in Casagrande cup and grooved.

2. Count blows needed to close groove at 12 mm.

3. Repeat for multiple water contents and plot LL graph.

For Plastic Limit (PL):

1. Roll soil to 3 mm threads.

2. When it crumbles, that moisture content is PL.

Shrinkage Limit (SL):

Done using shrinkage dish, dried, and volume change is observed.

Result:

- Plasticity Index (PI) = LL – PL

- Indicates consistency and behavior of soil with moisture.

6. Free Swell Index Test – IS 2720 Part 40

Purpose: To measure the swelling potential of expansive soils like black cotton soil.

Apparatus Used:

- Two 100 ml graduated cylinders

- Oven-dried soil sample

- Distilled water

- Kerosene

Procedure:

1. 10 g of dry soil is placed in one cylinder with water and one with kerosene.

2. Let stand for 24 hours.

3. Measure final volume of soil in both.

- Formula:

- FSI (%) = [(Vw – Vk) / Vk] × 100

- Where:

- Vw = Volume in water

- Vk = Volume in kerosene

Result:

- FSI < 50% → Low swelling

- 50–100% → Medium

- > 100% → High swelling potential

7. Compaction Test (Standard Proctor Test) – IS 2720 Part 7

Purpose: To determine the Optimum Moisture Content (OMC) and Maximum Dry Density (MDD) for soil compaction in the field.

Apparatus Used:

- Proctor mold and rammer (2.6 kg, 310 mm drop)

- Oven

- Weighing balance

- Moisture cans

Procedure:

1. Soil is mixed with water in increments.

2. Compacted in 3 layers with 25 blows each.

3. Each sample is weighed and dried for moisture.

4. Dry density is calculated and plotted against moisture content.

Result:

- Graph gives MDD and OMC.

- Used for field compaction specifications.

8. Unconfined Compression Test (UCC) – IS 2720 Part 10

Purpose: To determine the unconfined compressive strength of cohesive soils, especially clay, without lateral confinement.

Apparatus Used:

- Compression testing machine

- Proving ring or load cell

- Dial gauge

- Split mold for sample preparation

- Vernier caliper

Procedure:

1. Prepare a cylindrical soil sample (usually 38 mm dia × 76 mm height).

2. Place it in the loading frame without lateral support.

3. Apply axial load at a constant strain rate.

4. Record load and deformation until failure.

Formula:

UCS = (Peak Load) / (Cross-sectional Area)

If the sample fails with no lateral strain:

Cohesion, C = UCS / 2

Result: Helps in stability analysis of slopes, foundations, retaining walls, etc.

9. Direct Shear Test – IS 2720 Part 13

Purpose: To determine the shear strength parameters (cohesion ‘C’ and angle of internal friction ‘φ’) of soil.

Apparatus Used:

- Direct shear box

- Loading frame

- Proving ring

- Dial gauge

- Weights

Procedure:

1. Soil sample is placed in a two-part shear box.

2. Normal load is applied.

3. Horizontal load is applied at a constant rate to induce shear.

4. Record shear load vs displacement.

Result:

Plot shear stress vs normal stress.

From Mohr-Coulomb envelope:

τ = c + σ tan φ

10. Triaxial Shear Test – IS 2720 Part 11

Purpose: To determine shear strength of soil under controlled drainage conditions (UU, CU, CD tests).

Apparatus Used:

- Triaxial cell

- Loading frame

- Pressure chamber

- Deformation measuring devices

- Pore pressure measuring unit

Procedure:

1. Prepare cylindrical soil sample and mount in a membrane.

2. Place in triaxial cell, apply confining pressure.

3. Apply axial load (drained/undrained conditions based on test type).

4. Record stress-strain and pore pressure data.

Types of Test:

- UU: Unconsolidated Undrained

- CU: Consolidated Undrained

- CD: Consolidated Drained

Result: Gives shear parameters, pore pressure, and effective stress strength.

11. Consolidation Test – IS 2720 Part 15

Purpose: To determine the settlement characteristics of soil under long-term loading, including coefficient of consolidation (Cv) and compression index (Cc).

Apparatus Used:

- Consolidometer (oedometer)

- Dial gauge

- Load frame

- Water bath

Procedure:

1. Soil sample is placed in consolidation ring.

2. Vertical load is applied in increments.

3. Record settlement over time until primary consolidation is complete.

4. Repeat for higher loads.

Result:

- Settlement curve (log-time vs settlement)

- Compression Index (Cc), Coefficient of consolidation (Cv), and Permeability (k)

12. Permeability Test – IS 2720 Part 17

Purpose: To determine coefficient of permeability (k) of soils for seepage and drainage studies.

Apparatus Used:

- Constant head or Falling head permeameter

- Manometer

- Soil specimen

- Stopwatch

Procedure:

Constant Head (for coarse soils):

1. Maintain constant water head over soil sample.

2. Measure volume of water passing in known time.

Falling Head (for fine soils):

1. Observe falling water level in standpipe over time.

Formula:

For Falling Head:

k = (aL / At) × ln(h1/h2)

Where:

a = area of standpipe

A = area of specimen

L = length of specimen

h1, h2 = initial and final heads

Result:

Determines drainage capacity and seepage control needs.

13. Differential Free Swell Test – IS 2720 Part 40

Purpose: To identify expansive soils by evaluating their swelling potential.

Apparatus Used:

- Two 100 ml measuring cylinders

- Oven-dried soil sample

- Distilled water and kerosene

Procedure:

1. Add 10 g of soil in one cylinder with water, another with kerosene.

2. Allow to settle for 24 hours.

3. Measure final volume of soil in both liquids.

Formula:

Free Swell Index = [(Vw – Vk) / Vk] × 100

Same as previously explained.

Result:

Identifies soil behavior under moisture fluctuation — critical in black cotton soil areas.

14. California Bearing Ratio (CBR) Test – IS 2720 Part 16

Purpose: To evaluate subgrade strength of soil for pavement design.

Apparatus Used:

- CBR testing machine

- Mould with collar

- Penetration piston

- Dial gauges

- Weights for surcharge

Procedure:

1. Compact soil in mould (unsoaked or soaked condition).

2. Apply surcharge weights if needed.

3. Penetrate plunger at 1.25 mm/min.

4. Record load at 2.5 mm and 5 mm penetration.

Formula:

CBR (%) = (Test Load / Standard Load) × 100

Standard Loads:

2.5 mm = 1370 kg

5 mm = 2055 kg

Result:

CBR value (%) is used for design of flexible pavements.

Books

- Soil Mechanics and Foundations – B.C. Punmia

- Basic and Applied Soil Mechanics – Gopal Ranjan & A.S.R. Rao

- Geotechnical Engineering – C. Venkatramaiah

- IS 2720 (Parts 1–40)

- Principles of Geotechnical Engineering – Braja M. Das

Conclusion

When we think of construction, we often picture steel, concrete, and towering cranes. But beneath all of it—quite literally—lies soil, the true foundation of every structure. Over the course of this blog, we’ve explored the many layers (pun intended) of soil. From understanding what soil is, its types, properties, and how we classify it, to the different tests we run in the field and laboratory, it’s clear: soil is the silent partner in every engineering project.

Every project, whether it’s a small home or a massive flyover, starts with the ground. And that ground has a story to tell—if we know how to listen. That’s where proper soil investigation and testing come in. Whether you’re a student just getting into geotech, an engineer in the field, or someone working behind a desk designing foundations, knowing your soil is not optional—it’s essential.

Good soil can support your structure for decades. Bad soil, if ignored, can cost millions in repairs or worse, lead to collapse. That’s why we test it, classify it, and respect it. Because soil isn’t just “dirt”—it’s the bedrock of every safe structure.

Thank You Note

Thank you so much for reading till the end. If you’ve made it this far, you probably know by now just how important soil is—not just in engineering, but in shaping everything we build.

This blog was written with a lot of love (and research) for students, engineers, consultants, and even curious learners who want to understand the ground beneath their feet. Whether you’re preparing for an exam, starting a project, or simply geeking out on geotech—thank you for letting us to be part of your journey.

If you found this guide useful, feel free to share it with others in the construction industry. Stay tuned for more informative content on construction materials and testing methods.

Happy learning and building!

Frequently Asked Questions (FAQs)

Why is soil testing important before construction?

Can we use soil in an environmentally friendly way?

What’s the use of soil in infrastructure besides foundations?

What’s the big difference between field tests and lab tests?

How is soil classified in India?

Which soils are best for construction?

What is specific gravity in soil, and why does it matter?

Note for Readers

If you’d like to read this blog in your regional language or any other international language, simply click on the Google Translator option located in the bar at the top of the page. This feature allows you to select your preferred language and enjoy the content in a way that’s comfortable for you. We hope this makes your reading experience more enjoyable and accessible!

Disclaimer

This article is written for learning and reference purposes. While every effort has been made to ensure accuracy using standard codes like IS 2720 and IS 1498, always consult a licensed geotechnical engineer or IS codebook before applying this knowledge on real-world projects.

For more exciting topics, explore our other articles here

2 Comments