PCC vs RCC in Construction: Key Differences Every Engineer Should Know -Discover the key differences between PCC (Plain Cement Concrete) and RCC (Reinforced Cement Concrete) in construction. Learn their uses, strengths, and when to choose each type for better structural performance.

Table of Contents

Introduction

When it comes to construction, concrete plays a crucial role in providing strength and durability to structures. However, not all concrete is the same. Two common types used in building projects are PCC (Plain Cement Concrete) and RCC (Reinforced Cement Concrete). While both consist of cement, sand, aggregate, and water, the major difference lies in reinforcement.

PCC is a simple mixture of cement and aggregate without steel reinforcement. It is mainly used for non-structural elements such as flooring, leveling, and pavement. On the other hand, RCC includes steel bars (reinforcement) that add extra strength, making it ideal for load-bearing structures like beams, columns, and slabs.

Understanding the differences between PCC and RCC is essential for civil engineers, architects, and builders to make informed decisions. In this blog, we will explore their composition, properties, applications, and key differences to help you determine when to use each type of concrete in construction projects.

PCC vs RCC: Comparison on 15 Factors

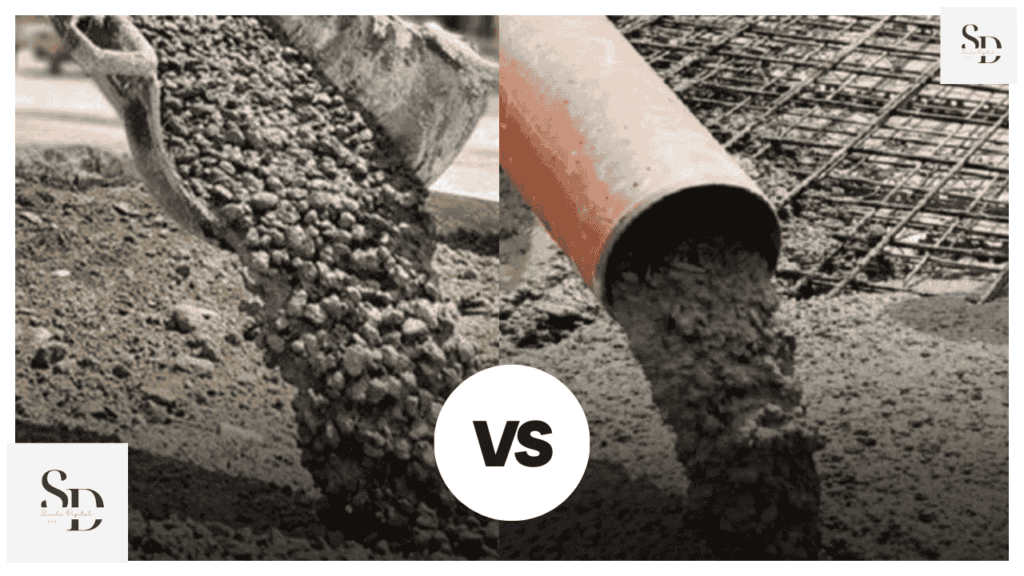

1. Composition

PCC: Made of cement, sand, aggregates, and water.

RCC: Contains all components of PCC but also includes steel reinforcement bars (rebars) to enhance strength.

2. Strength

PCC: High compressive strength but low tensile strength.

RCC: High strength in both compression and tension due to steel reinforcement.

3. Tensile Strength

PCC: Very weak in tension and cracks easily under stress.

RCC: Strong in tension due to embedded steel bars.

4. Load-Bearing Capacity

PCC: Suitable for light loads only.

RCC: Can handle heavy loads due to reinforcement.

5. Durability

PCC: Durable in normal conditions but prone to cracking under heavy loads.

RCC: Highly durable and resistant to cracking.

6. Cost

PCC: More affordable as it does not require steel reinforcement.

RCC: More expensive due to the cost of steel and additional labor.

7. Construction Process

PCC: Simple and easy to mix and place.

RCC: Requires careful placement of reinforcement, formwork, and skilled labor.

8. Applications

PCC: Used in flooring, pavements, road sub-base, and non-load-bearing walls.

RCC: Used in beams, columns, slabs, bridges, foundations, and high-rise buildings.

9. Cracking Resistance

PCC: Prone to cracks due to lack of reinforcement.

RCC: Less likely to crack due to reinforcement holding it together.

10. Corrosion Resistance

PCC: No steel reinforcement, so no risk of corrosion.

RCC: Steel inside can corrode if exposed to moisture and not properly maintained.

11. Maintenance Requirements

PCC: Requires minimal maintenance after setting.

RCC: Needs regular maintenance to prevent corrosion and structural weakening.

12. Fire Resistance

PCC: Good fire resistance due to its composition.

RCC: Better fire resistance, but steel can lose strength at high temperatures.

13. Weight

PCC: Lighter in weight due to the absence of steel.

RCC: Heavier due to embedded steel bars.

14. Environmental Impact

PCC: Lower environmental impact since it uses fewer resources.

RCC: Higher impact due to steel production and energy consumption.

15. Lifespan

PCC: Moderate lifespan, especially in high-load areas.

RCC: Long lifespan, lasting decades with proper maintenance.

Basic Points About PCC and RCC

1. What is PCC (Plain Cement Concrete)?

PCC (Plain Cement Concrete) is a construction material composed of cement, sand, aggregate, and water, without any steel reinforcement. It is mainly used for flooring, pavements, foundation beds, and leveling courses where structural strength is not required.

2. What is RCC (Reinforced Cement Concrete)?

RCC (Reinforced Cement Concrete) is a type of concrete that contains steel reinforcement bars (rebars) to improve its tensile strength. It is used in structural elements such as beams, columns, slabs, foundations, and bridges, where high strength and load-bearing capacity are required.

3. Density of PCC and RCC

Density of PCC: 2,400 kg/m³ (Approximately)

Density of RCC: 2,500 – 2,600 kg/m³ (Due to added steel reinforcement)

4. Weight Per Meter of PCC and RCC

Weight of PCC per cubic meter = 2,400 kg

Weight of RCC per cubic meter = 2,500 – 2,600 kg

5. Strength of PCC and RCC

Compressive Strength of PCC: 15-30 MPa (Megapascals)

Compressive Strength of RCC: 25-60 MPa (Varies based on design and reinforcement)

6. Applications of PCC and RCC

PCC is used for:

Floor leveling

Road pavements

Footpaths and sidewalks

Foundation beds

Non-load-bearing walls

RCC is used for:

Beams, columns, and slabs

Bridges and flyovers

Dams and water tanks

High-rise buildings

Foundations for heavy structures

Advantages and Disadvantages of PCC vs RCC

Both Plain Cement Concrete (PCC) and Reinforced Cement Concrete (RCC) have their own strengths and weaknesses. Let’s compare them based on their advantages and disadvantages to understand where each type is more suitable.

Advantages of PCC (Plain Cement Concrete)

Cost-Effective: PCC is cheaper compared to RCC because it does not require steel reinforcement.

Easy to Mix and Place: Since it only consists of cement, sand, aggregate, and water, PCC is simple to prepare and apply.

Resistant to Corrosion: Since there are no steel bars, PCC does not suffer from rusting or corrosion.

Low Maintenance: Once set, PCC requires minimal maintenance and can last a long time in the right conditions.

Good for Leveling and Base Layers: PCC is ideal for non-structural applications such as flooring, road sub-base, and foundation bedding.

Disadvantages of PCC

Low Tensile Strength: PCC cannot withstand tension (pulling forces) and cracks easily under stress.

Brittle Nature: Since there is no reinforcement, it is more prone to cracking and breaking under heavy loads.

Not Suitable for Structural Components: PCC is not strong enough for load-bearing structures like beams, columns, and slabs.

Limited Use: It is mostly used as a base material and cannot be used in places requiring high strength.

Advantages of RCC (Reinforced Cement Concrete)

High Strength: The addition of steel reinforcement makes RCC strong in both compression and tension.

Versatile in Construction: It is used for beams, columns, slabs, bridges, dams, and almost all structural components.

Durable and Long-Lasting: RCC structures can last for decades if maintained properly.

Can Withstand Heavy Loads: Due to steel reinforcement, RCC can handle heavy loads, making it suitable for high-rise buildings and bridges.

Fire and Weather Resistant: RCC offers good resistance to fire, water, and harsh weather conditions.

Disadvantages of RCC

Expensive: The cost of steel reinforcement makes RCC more expensive than PCC.

Complex Construction Process: RCC requires skilled labor for reinforcement placement, formwork, and curing.

Prone to Corrosion: The steel inside RCC can rust if not properly protected, leading to structural damage over time.

Heavier Structure: RCC structures are heavy, requiring strong foundations to support the weight.

Time-Consuming: The construction process of RCC is longer due to the need for reinforcement placement and curing time.

Grades of PCC (Plain Cement Concrete)

M5 (1:5:10) – Used for very light-duty works.

M7.5 (1:4:8) – Used for foundation beds and base layers.

M10 (1:3:6) – Used for leveling courses and non-structural works.

M15 (1:2:4) – Used for flooring and simple foundation work.

Grades of RCC (Reinforced Cement Concrete)

M20 (1:1.5:3) – Minimum grade for structural RCC, used for slabs and beams.

M25 (1:1:2) – Used for columns, slabs, and residential buildings.

M30 (Design Mix) – Used for commercial buildings and reinforced structures.

M35 (Design Mix) – Used for heavy-duty structures like bridges.

M40 (Design Mix) – Used for high-rise buildings and bridges.

M50 and above (Design Mix) – Used for industrial and special structures like dams.

Nominal Mix vs. Design Mix Concrete

Nominal Mix Concrete – Uses a fixed ratio of cement, sand, and aggregates (e.g., M5 to M25). It is suitable for small-scale construction and non-structural works.

Design Mix Concrete – The mix is customized based on strength requirements, calculated by engineers (e.g., M25 and above). It is used in high-strength structural projects like bridges, high-rises, and industrial structures.

Indian Standard (IS) codes

IS Code for PCC (Plain Cement Concrete)

- IS 456: 2000 – General code for Plain and Reinforced Concrete.

- IS 383: 2016 – Specifies requirements for fine and coarse aggregates in PCC.

- IS 10262: 2019 – Guidelines for concrete mix proportioning.

- IS 4031: 1988 – Covers testing methods for cement used in PCC.

IS Code for RCC (Reinforced Cement Concrete)

- IS 456: 2000 – General code for design and construction of RCC structures.

- IS 3370: 2009 – Guidelines for RCC water-retaining structures.

- IS 13920: 2016 – Ductile detailing of RCC structures for seismic zones.

- IS 2911: 2010 – Code for design and construction of pile foundations in RCC.

- IS 4926: 2003 – Covers ready-mix concrete used in RCC.

Books

1. Design of Reinforced Concrete Structures – N. Subramanian

2. Reinforced Concrete Design – B.C. Punamia, Ashok Kumar Jain, Arun Kumar Jain

3. Reinforced Cement Concrete (RCC) Design – S.C. Gupta

4. Plain and Reinforced Concrete for Dummies – H. K. Gupta

5. Reinforced Concrete Structures – Robert Park, Thomas Paulay

6. Reinforced Concrete: Mechanics and Design – James K. Wight, James G. MacGregor

7. Plain Concrete Construction – William Kirby

8. Reinforced Concrete Design to Eurocode 2 – Bill Mosley, John Bungey, Ray Hulse

9. Concrete Technology: Theory and Practice – M.S. Shetty

10. Advanced Reinforced Concrete Design – P.C. Varghese

Conclusion

Concrete is the backbone of modern construction, and understanding the differences between Plain Cement Concrete (PCC) and Reinforced Cement Concrete (RCC) is essential for engineers, builders, and architects. While both materials share common components such as cement, sand, aggregate, and water, their structural capabilities and applications differ significantly.

PCC is an excellent choice for non-load-bearing applications such as flooring, leveling, and road sub-base layers. It is cost-effective, easy to mix, and requires minimal maintenance. However, its low tensile strength and brittleness make it unsuitable for load-bearing structures.

RCC, on the other hand, is reinforced with steel bars, making it strong in both compression and tension. It is used in beams, columns, slabs, bridges, and other critical structures where strength and durability are necessary. Although it is more expensive and requires skilled labor, its high load-bearing capacity and long lifespan make it the preferred choice for major construction projects.

Choosing between PCC and RCC depends on various factors, including budget, application, load requirements, and durability expectations. If the goal is to create a solid foundation or base, PCC is the ideal option. However, for structural components requiring high strength and resistance, RCC is the superior choice.

By carefully evaluating these aspects, civil engineers and construction professionals can optimize project efficiency, reduce costs, and ensure long-term safety and stability.

Thank You Note

Thank you for taking the time to read this detailed comparison between PCC and RCC. We hope this guide has helped you understand their key differences, advantages, disadvantages, and applications. Choosing the right type of concrete is essential for ensuring cost efficiency, durability, and structural integrity in construction projects.

For more comparisons and insights, visit our blog regularly. If you have any questions or suggestions, feel free to leave a comment or contact us directly. Happy building!

Frequently Asked Questions (FAQs)

What is the main difference between PCC and RCC?

Where is PCC commonly used?

Why is steel used in RCC?

Which is more expensive, PCC or RCC?

Can PCC be used for constructing buildings?

What are the major disadvantages of RCC?

How can the durability of RCC structures be increased?

Use high-quality materials (cement, sand, aggregates, and reinforcement).

Ensure proper curing and compaction.

Apply anti-corrosive coatings to steel reinforcement.

Perform regular maintenance to check for cracks and corrosion.

Note for Readers

If you’d like to read this blog in your regional language or any other international language, simply click on the Google Translator option located in the bar at the top of the page. This feature allows you to select your preferred language and enjoy the content in a way that’s comfortable for you. We hope this makes your reading experience more enjoyable and accessible!

Disclaimer

This article is intended for educational and informational purposes only. The information provided here is based on general construction practices and engineering principles. Before making any construction decisions, it is always recommended to consult a professional civil engineer or contractor to assess site-specific requirements and structural needs. The author is not responsible for any misuse, misinterpretation, or consequences arising from the use of this information.

For more exciting topics, explore our other articles here

5 Comments